STAHLWILLE 730 Quick Torque wrench service MANOSKOP® with Holder for Insert Tools

Size 5 (5-35 FT-LB)

Size 5 (5-35 FT-LB) Size 12 (20-95 FT-LB)

Size 12 (20-95 FT-LB) Size 20 (30-144 FT-LB)

Size 20 (30-144 FT-LB) Size 40 (60-300 FT-LB)

Size 40 (60-300 FT-LB) Size 65 (100-480 FT-LB)

Size 65 (100-480 FT-LB)Overview

|

QuickRelease

QuickSelect

Low-wear bending beam system

2-component handle

DIN EN ISO 6789-2

|

Features

- Robust, low-maintenance mechanical torque wrench for controlled screw tightening.

- Clicking occurs with a clear haptic and acoustic click signal.

- Quick torque setting via the easy-to-operate clamping lever in the handle.

- Durable, low-wear flexible rod clicking system eliminates the need to reset to '0'.

- Quick adjustment from the outside possible without disassembly.

Specifications

- Clicking type with dual stop signal

- No reset to '0' required

- The measuring element is only under load when a force is applied.

- With holder for interchangeable insert tools

- With QuickRelease safety lock

- Non-slip adjuster with thumb recess for quick torque adjustment

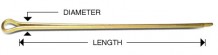

- Fine, tapered pointers

- Dual scale N·m/ft·lb

- Also available on request as a N·m only version without dual scale

- Counter-clockwise tightening by turning the insert tool over

- Clicking mechanism insensitive to continuous loads and counter-loads (up to the max. measurement range of the torque wrench)

- Optimal calibration with perfectControl® calibration systems No. 7794 or alibration systems No. 7706, 7791

- Easy adjustment without disassembly via 2 external adjustment screws

- With 2-component handle

- Calibration certificate in accordance with DIN EN ISO 6789-2:2017

- Accuracy ±4 %

Benefits

- Rapid adjustment.

- Easy and quick adjustment of the torque is carried out by an easy-to-operate clamping lever in the handle. The scale can be moved quickly and safely with an ergonomically shaped, non-slip adjustment element with thumb recess.

- Adjustment does not require disassembly.

- Quick adjustment from outside, no disassembly of the torque wrench required, with 2 adjustment points for the maximum & minimum values.

Aircraft Spruce Australia

Aircraft Spruce Australia