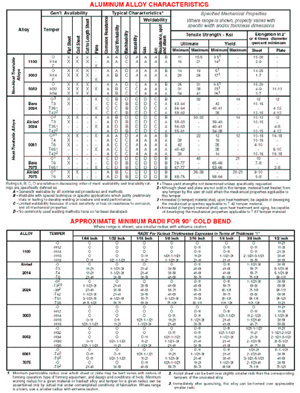

1100

This grade is commercially pure aluminum. It is soft and ductile and has

excellent workability. It is ideal for applications involving intricate

forming because it work hardens more slowly than other alloys. It is the

most weldable of aluminum alloys, by any method. It is non heat-treatable.

It has excellent resistance to corrosion and is widely used in the chemical

and food processing industries. It responds well to decorative finishes

which make it suitable for giftware.

2011

This is the most free-machining of the

common aluminum alloys. It also has excellent mechanical properties.

Thus, it is widely used for automatic screw machine products in parts

requiring extensive machining.

2014 & 2017

The 2017 alloy combines excellent

machinability and high strength with the result that it is one of the

most widely used alloys for automatic screw machine work. It is a tough,

ductile alloy suitable for heavy-duty structural parts. Its strength

is slightly less than that of 2014.

2024

This is one of the best known of the high

strength aluminum alloys. With its high strength and excellent fatigue

resistance, it is used to advantage on structures and parts where good

strength-to-weight ratio is desired. It is readily machined to a high

finish. It is readily formed in the annealed condition and may be subsequently

heat treated. Arc or gas welding is generally not recommended, although

this alloy may be spot, seam or flash welded. Since corrosion resistance

is relatively low, 2024 is commonly used with an anodized finish or

in clad form (“Alclad”) with a thin surface layer of high purity aluminum.

Applications: aircraft structural components, aircraft fittings, hardware,

truck wheels and parts for the transportation industry.

3003

This is the most widely used of all aluminum

alloys. It is essentially commercially pure aluminum with the addition

of manganese which increases the strength some 20% over the 1100 grade.

Thus, it has all the excellent characteristics of 1100 with higher strength.

It has excellent corrosion resistance. It has excellent workability

and it may be deep drawn or spun, welded or brazed. It is non heat treatable.

Applications: cooking utensils, decorative trim, awnings, siding, storage

tanks, chemical equipment.

5005

This alloy is generally considered to be

an improved version of 3003. It has the same general mechanical properties

as 3003 but appears to stand up better in actual service. It is readily

workable. It can be deep drawn or spun, welded or brazed. It has excellent

corrosion resistance. It is non heat-treatable. It is well suited for

anodizing and has less tendency to streak or discolor. Applications

same as 3003.

5052

This is the highest strength alloy of the

more common non heat-treatable grades. Fatigue strength is higher than

most aluminum alloys.In addition this grade has particularly good resistance

to marine atmosphere and salt water corrosion. It has excellent workability.

It may be drawn or formed into intricate shapes and its slightly greater

strength in the annealed condition minimizes tearing that occurs in

1100 and 3003. Applications: Used in a wide variety of applications

from aircraft components to home appliances, marine and transportation

industry parts, heavy duty cooking utensils and equipment for bulk processing

of food.

5083 & 5086

For many years there has

been a need for aluminum sheet and plate alloys that would offer, for

high strength welded applications, several distinct benefits over such

alloys as 5052 and 6061. Some of the benefits fabricators have been

seeking are greater design efficiency, better welding characteristics,

good forming properties, excellent resistance to corrosion and the same

economy as in other non heat-treatable alloys. Metallurgical research

has developed 5083 and 5086 as superior weldable alloys which fill these

needs. Both alloys have virtually the same characteristics with 5083

having slightly higher mechanical properties due to the increased manganese

content over 5086. Applications: unfired pressure vessels, missile containers,

heavy-duty truck and trailer assemblies, boat hulls and superstructures.

6061

This is the least expensive and most versatile

of the heat-treatable aluminum alloys. It has most of the good qualities

of aluminum. It offers a range of good mechanical properties and good

corrosion resistance. It can be fabricated by most of the commonly used

techniques. In the annealed condition it has good workability. In the

T4 condition fairly severe forming operations may be accomplished. The

full T6 properties may be obtained by artificial aging. It is welded

by all methods and can be furnace brazed. It is available in the clad

form (“Alclad”) with a thin surface layer of high purity aluminum to

improve both appearance and corrosion resistance. Applications: This

grade is used for a wide variety of products and applications from truck

bodies and frames to screw machine parts and structural components.

6061 is used where appearance and better corrosion resistance with good

strength are required.

6063

This grade is commonly referred to as the

architectural alloy. It was developed as an extrusion alloy with relatively

high tensile properties, excellent finishing characteristics and a high

degree of resistance to corrosion. This alloy is most often found in

various interior and exterior architectural applications, such as windows,

doors, store fronts and assorted trim items. It is the alloy best suited

for anodizing applications - either plain or in a variety of colors.

7075

This is one of the highest strength aluminum

alloys available. Its strength-to weight ratio is excellent and it is

ideally used for highly stressed parts. It may be formed in the annealed

condition and subsequently heat treated. Spot or flash welding can be

used, although arc and gas welding are not recommended. It is available

in the clad (“Alclad”) form to improve the corrosion resistance with

the over-all high strength being only moderately affected. Applications:

Used where highest strength is needed.

ALUMINUM

ALLOY DESIGNATIONS

The aluminum industry uses a four-digit index system

for the designation of its wrought aluminum alloys.

As outlined below, the first digit indicates the alloy

group according to the major alloying elements.

1xxx Series

In this group. minimum aluminum content is 99%. and

there is no major alloying element.

The second digit indicates modifications in impurity

limits. If the second digit is zero, there is no special control on

individual impurities. Digits 1 through 9, which are assigned consecutively

as needed, indicate special control of one or more individual impurities.

The last two digits indicate specific minimum aluminum

content. Although the absolute minimum aluminum content in this group

is 99% the minimum for certain grades is higher than 99%, and the last

two digits represent the hundredths of a per cent over 99.

Thus, 1030 would indicate 99.30% minimum aluminum.

without special control on individual impurities. The designations 1130,

1230, 1330, etc.. indicate the same purity with special control on one

or more impurities. Likewise. 1100 indicates minimum aluminum content

of 99.00% with individual impurity control.

2xxx through 9xxx Series

The major alloying elements are indicated by the first

digit, as follows:

2xxx Copper

3xxx Manganese

4xxx Silicon

5xxx Magnesium

6xxx Magnesium and silicon

7xxx Zinc

8xxx Other element

9xxx Unused series

The second digit indicates alloy modification. If the

second digit is zero. it indicates the original alloy: digits 1 through

9, which are assigned consecutively, indicate alloy modifications. The

last two digits have no special significance, serving only to identify

the different alloys in the group.

Experimental Alloys

Experimental alloys are designated according to the four digit system,

but they are prefixed by the letter X. The prefix is dropped when the

alloy becomes standard. During development, and before they are designated

as experimental, new alloys are identified by serial numbers assigned

by their originators. Use of the serial number is discontinued when

the X number is assigned.

ALUMINUM

TEMPER DESIGNATIONS

Temper designations of wrought aluminum alloys consist

of suffixes to the numeric alloy designations. For example, in 3003-H14,

3003 denotes the alloy and “H14” denotes the temper, or degree of hardness.

The temper designation also reveals the method by which the hardness

was obtained. Temper designations differ between non heat-treatable

alloys and heat-treatable alloys. and their meanings are given below:

Non Heat-Treatable Alloys

The letter “H” is always followed by 2 or 3 digits.

The first digit indicates the particular method used to obtain the temper.

as follows:

— Hl means strain hardened only.

— H2 means strain hardened, then partially annealed.

— H3 means strain hardened, then stabilized.

The temper is indicated by the second digit as follows:

2 1/4 hard

4 I/2 hard

6 3/4 hard

8 full hard

9 extra hard

Added digits indicate modification of standard practice.

Heat-Treatable Alloys

-F As fabricated

-O Annealed

-T Heat treated

The letter “T” is always followed by one or more digits.

These digits indicate the method used to produce the stable tempers,

as follows:

-T3 Solution heat treated, then cold worked.

-T351 Solution heat treated, stress-relieved stretched,

then cold worked.

-T36 Solution heat treated, then cold worked (controlled).

-T4 Solution heat treated, then naturally aged.

-T451 Solution heat treated, then stress relieved

stretched.

-T5 Artificially aged only.

-T6 Solution heat treated, then artificially aged.

-T61 Solution heat treated (boiling water quench),

then artificially aged.

-T651 Solution heat treated, stress-relieved stretched,

then artificially aged (precipitation heat treatment).

-T652 Solution heat treated, stress relieved by compression.

then artificially aged.

-T7 Solution heat treated, then stabilized.

-T8 Solution heat treated, cold worked, then artificially

aged.

-T81 Solution heat treated, cold worked (controlled),

then artificially aged.

-T851 Solution heat treated, cold worked, stress-relieved

stretched, then artificially aged.

-T9 Solution heat treated, artificially aged, then

cold worked.

-T10 Artificially aged, then cold worked.

Added digits indicate modification of standard practice.

COMPARISON

OF MODERN &

OLD SYSTEMS OF ALUMINUM ALLOY DESIGNATION

Although the old system of aluminum identification

has been obsolete for many years, stock with the old markings is still

occasionally found. The following comparison is presented as an aid

in identifying such materials in terms of the modern system.

In the old system, alloy composition was indicated

by a one- or two-digit number followed by the letter “S” to indicate

that it was a wrought alloy, i.e., an alloy that could be shaped by

rolling, drawing or forging. Any variation in the basic composition

was indicated by a letter preceding the numerical alloy designation.

For example, A17S was a modification of the basic alloy 17S. In modern

terminology these two alloys are designated 2117S and 2017S, respectively.

Temper was designated by a second letter: “O” for soft (annealed), “H”for

strain hardness of non heat-treatable alloys, and “T”for hardness of

heat-treatable alloys. Degree of hardness of non heat-treatable alloys

was indicated by a fraction preceding the letter “H”. For example, 3S1/4H

would be quarter-hard 3S alloy.

The following Table gives examples of the old and modern

designations of some common aluminum alloys.

|

Aircraft Spruce Australia

Aircraft Spruce Australia